Table of Contents

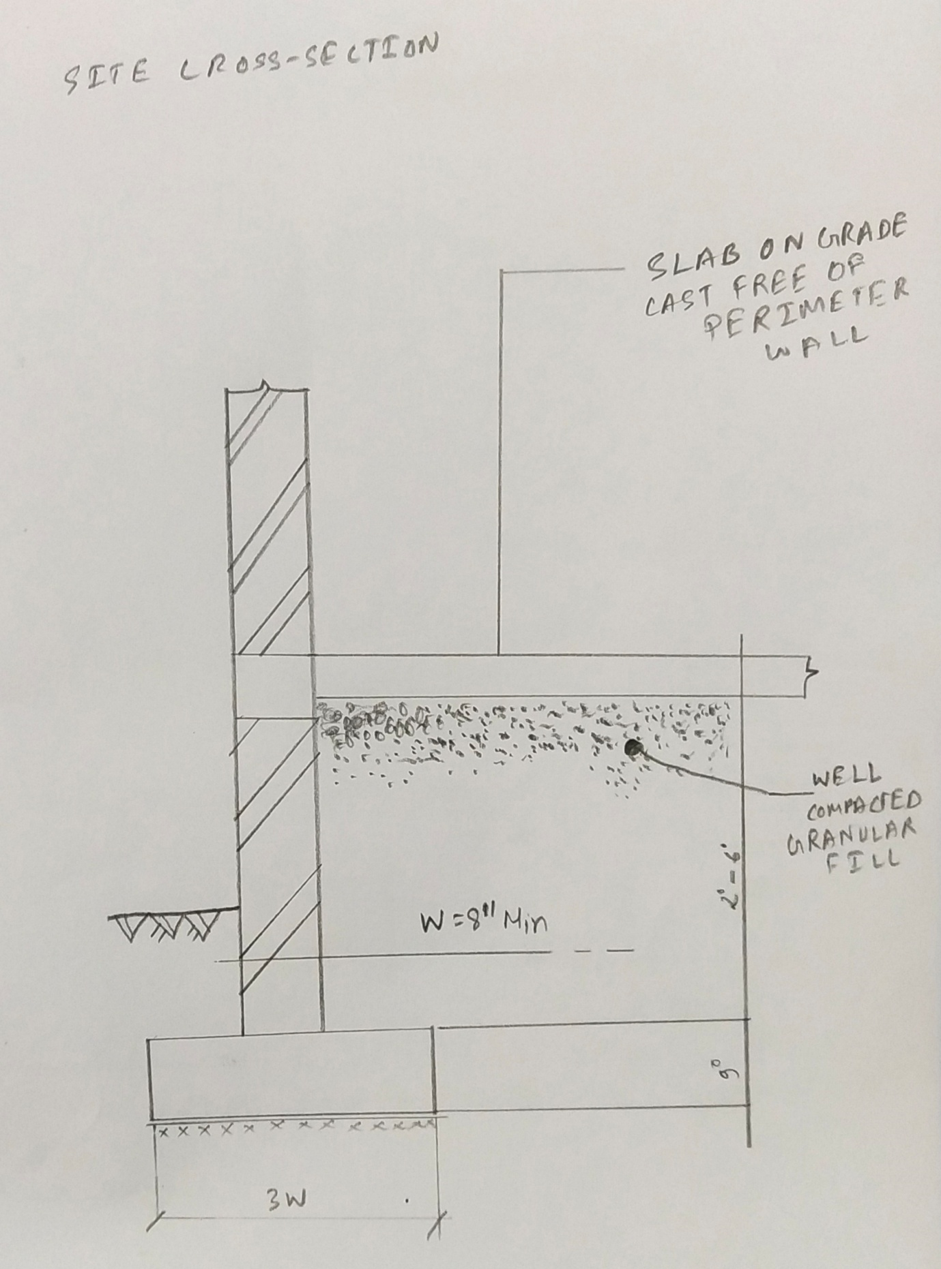

There are some strategies which are taken up by site officers. While I was going through the sites, I discovered that a nice concrete mix was getting cast. The concrete which was getting utilised was stiff. This is a different strategy used in these days. Still, this kind of shaping provides an excellent structure to the building which needs to be built (Fukuyama, 2017). The footings were getting cast with the help of concrete mix, which is stiff. I saw while the placement of formation of the footing was done, enough stones were being placed. The stone was large enough and was also placed on the zone, which was mucky. This zone was placed above the water table. Once of the stone was compacted into the "mud" than pouring of the footing was done.

Figure 1: Site Cross Section

(Source: Created by author)

Figure 2: Site for construction

Figure 3: Site for cross section

Figure 4: Construction of the building

Figure 5: Site for construction

Figure 6: Site for beam

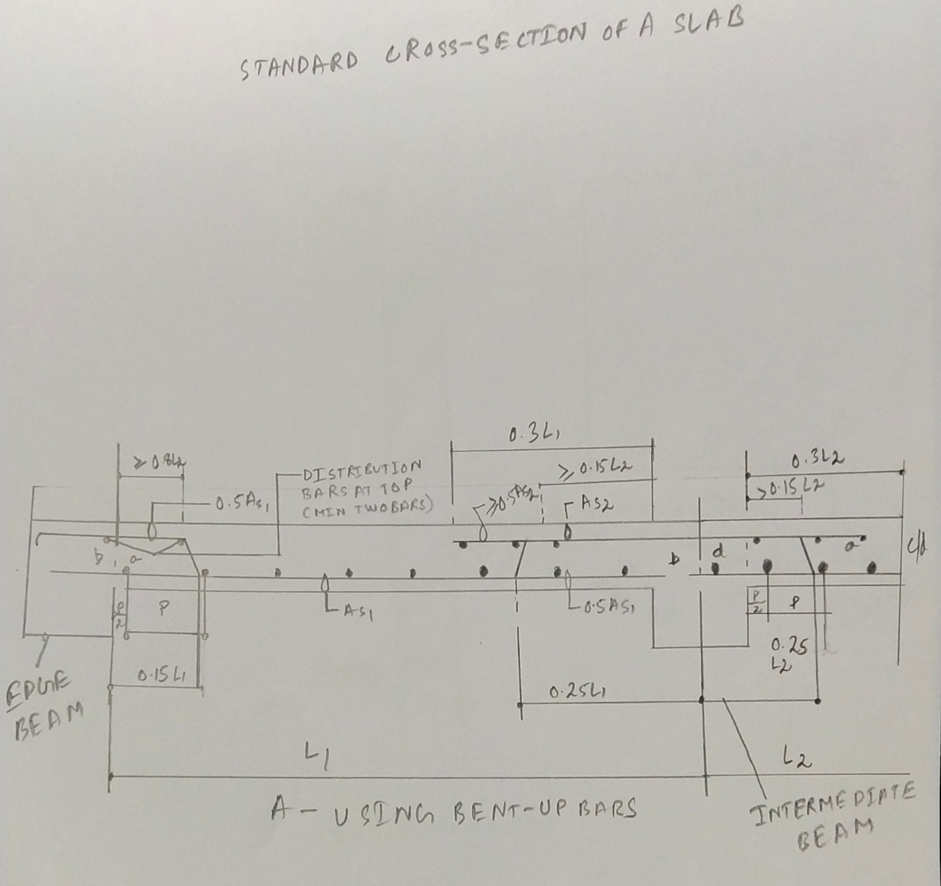

“Reinforced concrete slab” is the most common kind of slab used by the constructors. It is known for providing the best system for floor slabs. The formation may hold like one spinning kind of formation or also may hold like a two-way spinning kind of formation. These are utilized mainly in residential buildings. Though the use has always has been on the residential building, still, the site I visited is not a residential building. The images I have provided give an idea about it (Acharyya and Dey, 2018). The alternate method is used over here. This strategy is by using a precast form of a system consisting of the "reinforced concrete beam slab". The guideline which needs to be followed in this kind of system is like that of BS 8110. This is a composite system; still, it can behave satisfactorily.

I want to suggest this alternative due to its functionalities, but the residential building needs to use the standard "reinforced concrete slab" (Acharyya and Dey, 2018). This is cheap in terms of money and provides a lot of efficiencies. This kind of cost-effective strategy can be taken up by site engineers. There are no reasons according to me in not adopting this system.

The current situation is pretty much as I saw that the slabs were about to be placed on the sites. The sites are well maintained from the beginning. The materials are present, and the next step is the building up of the slabs. The standard design for a particular slab that can be used up over here is provided by me (Markou et al. 2015). The slabs that I have provided work fine if torsion reinforcement is done. This kind of reinforcement is to be used at any corner as the edges are held firmly in the corners. These edges are required to be stopped from any lifting, and the consequences holding the reinforcement in terms of any cracking are negligible.

There are few stages which are followed over here. These stages are:

- The site needs to be labeled and preparation of it is required to be done. The site is leveled properly after cleaning it.

- The trenches need to be digged for PCC as well as excavation

- The next step is to properly reinforce the foundation as it transfers the overall load to the building.

- The reinforcements for the ground beam are done and then concreting it. The voids are mainly filled with the soils which are compact.

Some of the materials required for constructing the slab in a much better manner so that there is no sign of any deflection or cracking are:

- Aggregates

- Cement

- Linseed oil (These are mainly utilised for large buildings)

- Shuttering ( can be made by an iron as well as wood)

- Dust

- Sand

- Water

- Bars required for the reinforcement consisting of different kinds of diameters

The concrete floor that must be of standard quality must include thickness within the slab. In the case of residential buildings, the thickness needs to be 4 inches. Sometimes “five to six” inches can also be used as the concrete may take up some of the heavier loads (Nowotarski et al. 2019). During the preparation of the base, the ground level is required to be cut down for proper depth. This will allow creating a particular portion of thickness for the slab.

Figure 2: Slab preparation

(Source: Created by author)

A better form of finishing along with the stages of concrete flooring cannot be done if there is an availability of the fresh frozen form of concrete. These need to be there only for the first "24 hours" in most of the cases, but there is a loss of around 50 per cent of its full strength. So, the temperature just above 39 Fahrenheit would be perfect.

The recommended value for the slab size is using a thickness of around 4 inches.

The first step needs to be done appropriately preparing the "ground works for the slab". The digging must be done for proper depth.

Embedding tools can be used for defining proper specifics regarding the reinforcement.

Book

Fukuyama, F., 2017. State building: Governance and world order in the 21st century. UK: Profile Books.

Journals

Acharyya, R. and Dey, A., 2018. Assessment of failure mechanism of a strip footing on the horizontal ground considering flow rules. Innovative Infrastructure Solutions, 3(1), p.49.

Acharyya, R. and Dey, A., 2018. Importance of dilatancy on the evolution of failure mechanism of a strip footing resting on horizontal ground. INAE Letters, 3(3), pp.131-142.

Markou, G., Sabouni, R., Suleiman, F. and El-Chouli, R., 2015. Full-scale modelling of the soil-structure interaction problem through the use of hybrid models (HYMOD). International Journal of Current Engineering and Technology, 5(2), pp.885-899.

Nowotarski, P., Szymanski, P. and Rzepecka, P., 2019, January. DMAIC Method of Quality Improvement of Ground Works Processes: Case Study. In IOP Conference Series: Earth and Environmental Science (Vol. 221, No. 1, p. 012002). IOP Publishing.